| HOME

|

|||||||||||

Prevention of air bubbles in LCD panels. A wide range of models.

Autoclaves for LCD Panel

PTU series

PTU series

line up:PTU-305VⅢ / PTU-507H / PTU-807H

■ Features & Functions

Setting of appropriate condition is easy.

It is possible to create appropriate conditions for removing air bubbles after sticking a polarizing plate in the LCD manufacturing process by setting temperature, pressure, and time in combination.

It is possible to create appropriate conditions for removing air bubbles after sticking a polarizing plate in the LCD manufacturing process by setting temperature, pressure, and time in combination.

Improving the adhesion strength between polarizing plate and cell

It is possible to increase the adhesion strength between the polarizing plate and cell after sticking the polarizing plate by applying heat and pressure.

It is possible to increase the adhesion strength between the polarizing plate and cell after sticking the polarizing plate by applying heat and pressure.

Each setting is easy.

As the high precision digital input system is employed for setting temperature, pressure, time, etc. , settings are easy.

(PTU-305VⅢ can set only temperature and time.)

As the high precision digital input system is employed for setting temperature, pressure, time, etc. , settings are easy.

(PTU-305VⅢ can set only temperature and time.)

High precision control system

The temperature control system is a PID control / SSR drive method, and the pressure control system is a ON / OFF control and solenoid valve open / close system or motor-driven valve open / close system, enabling high precision control.

The temperature control system is a PID control / SSR drive method, and the pressure control system is a ON / OFF control and solenoid valve open / close system or motor-driven valve open / close system, enabling high precision control.

Equipped with various safety devices including interlock mechanism

The door clamping method employs a clutch system driven by gears with secure interlock mechanism. (PTU-305VIII uses the eye bolts for clamping) The chamber is made of stainless steel and the over-temperature prevention device, over-pressure prevention device, pressure safety valve, etc. are installed.

The door clamping method employs a clutch system driven by gears with secure interlock mechanism. (PTU-305VIII uses the eye bolts for clamping) The chamber is made of stainless steel and the over-temperature prevention device, over-pressure prevention device, pressure safety valve, etc. are installed.

Applicable to the heated and pressurized environments

This equipment is applicable not only to the removal of air bubbles in the liquid crystal display but also to the heated and pressurized environments.

This equipment is applicable not only to the removal of air bubbles in the liquid crystal display but also to the heated and pressurized environments.

A cycle time is shortened.

A warm-up function enables quick rise time and shorten the cycle time.

A warm-up function enables quick rise time and shorten the cycle time.

Required utilities

・Power supply: Refer to the specifications. Household outlets are not recommended.

・Power supply: Refer to the specifications. Household outlets are not recommended.

■ Options

| Recorder | Cabinet | Drawer type tray | |

|---|---|---|---|

|

|

|

|

| Recorder for temperature, humidity, pressure Recorder for temperature and humidity |

Cabinet for main body (PTU-507H) |

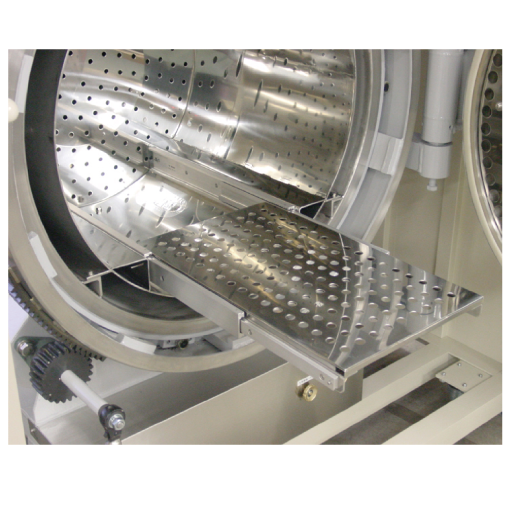

It can smoothly put in and out specimens. (PTU-507H / 807H) |

|

| Safety cover for lid | Exhaust duct | Stackable rack |

|---|---|---|

| For PTU-305VⅢ | For PTU-507H (with cabinet) For PTU-807H |

Chamber space can be effectively used. |

■ Specifications

| Autoclaves for LCD Panel | ||||||

|---|---|---|---|---|---|---|

| Model | PTU-305VⅢ | PTU-507H | PTU-807H | |||

| Outside dimensions (W x D x H mm) |

750 x 550 x 1050 | 850 x 1375 x 1650 | 1470 x 1515 x 1800 | |||

| Effective chamber size (φ x D mm) |

250 x 340 | 450 x 600 | 700 x 600 (Effective height: H400) |

|||

| Weight (Approximately) | 105 kg | 370 kg | 800 kg | |||

| Temperature control method | PID control, SSD drive | |||||

| Temperature | Working range | 50℃ - 100℃ (Service temp. 80℃) | 50℃ - 80℃ | |||

| Control accuracy | - | ±3℃ (No-load・50℃・0.5MPa) |

±2℃ (No-load・50℃・0.5MPa) |

|||

| Pressure control method | ON/OFF control, Solenoid valve open / close system | |||||

| Pressure | Working range | 0.196MPa - 0.490MPa | 0.05MPa - 0.69MPa | |||

| Control accuracy | - | ±0.01MPa | ||||

| Instrumentation | Temperature: Digital setting, Digital display Pressure: Digital setting, digital / analog display ※PTU-305VⅢ: Analog setting, analog display Time: Digital setting, digital display (Timer : 99 hr 59 min) | |||||

| Lid clamp method | Eye bolt clamping method | Clutch type lid clumping method | ||||

| Materials | Chamber: SUS304 Top panel: SUS304 Piping: Cu Exterior panel: SPCC, (baking finish) |

Chamber, inner chamber, lid,shelf: SUS304 Clutch claw, chamber support frame: SS400 (urethane coating) Control box: SECC and AL (baking finish) Piping: Cu |

Chamber, lid, shelf: SUS304 Clutch door (only clutch part): SS400 (epoxy resin paint) Piping: SUS304 and Cu Frame: SS400 L-shaped angle (baking finish) Exterior panel: SPCC and AL (baking finish) |

|||

| Pressure vessel category | Small sized pressure vessel | Second class pressure vessel | ||||

| Power supply | AC220V / 230V / 240V, 50Hz / 60Hz (Single phase) (Select one from the above power supply voltages, when placing an order.) | |||||

| Power connection | Ring terminal | |||||

| Safety devices | Safety pressure valve, Over-pressure prevention device, Low wtaer cut off device, Earth leakage breaker, Breaker for heater, Thermal fuse, Control fuse | |||||

| Supplied accessories | Power cord Pressure-proof hose x 2, Nut tightening tool x 1 | Power cord, Shelf x 2 | ||||

※The performance value was obtained when ambient temperature was normal and the test chamber was empty.

※Specifications and appearance are subject to change without notice due to continuous product improvement.